Engineering begins to translate ideas into reality. At The Metcalfe Group, we have the expertise in-house to design and engineer benefit-rich products with market-leading performance. One of our strengths is creativity and uncanny insight to solve very complex problems that other firms won’t touch. It’s one thing to create a pretty new product design, but quite another to engineer it and actually make it work. Clients come to us because we are respected in the industry for our proven performance – we even serve other product design firms that consult us for our respected opinions, design engineering, manufacturing methods, material selection, and structural analysis.

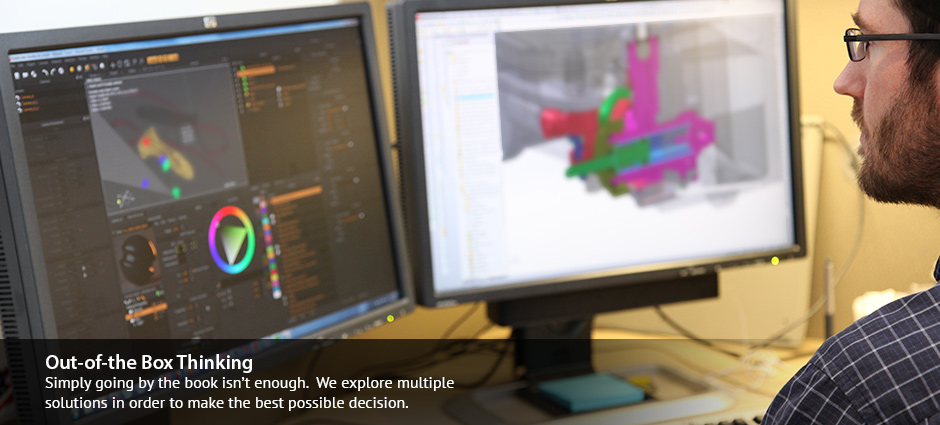

Creative Design Thinking

A stereotypical engineer might look at a problem and try to find a single solution that works within given constraints. That may work fine for many situations, but at The Metcalfe Group we see our role as innovating and being anything but typical. It’s obvious to us that stopping at only one solution will not create breakthroughs. We dig deep and tackle the problem from every imaginable angle, diverging far and wide before we converge toward the best ideas from the many conceived.

Our engineering team isn’t constrained by your organization’s usual way of thinking. While we will readily draw upon your organization’s experience and knowledge to favor a robust solution, we have the ability to start each project with a clean slate and even try things that may have unnecessary stigma.

Our broad experience and client diversity opens us up to new solutions that may be in an entirely unrelated, tangent, or adjacent market space. Additionally, we’re just plain curious and are tuned in to the world around us every hour of every day seeking new techniques and technologies that may be the ideal engineering solution for your next new product or line extension.

Deep Expertise & Powerful Tools

All this creativity wouldn’t be worth much if we didn’t have the ability to execute. Engineering is how we make products real, and to do that right requires knowledge, experience, and the right tools.

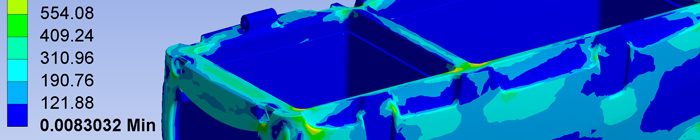

One powerful tool we utilize with great benefit and regularity is Finite Element Analysis, or FEA, in which we apply virtual forces to 3D CAD models and analyze how they react. We have performed structural and modal analysis on products ranging from small consumer and medical products to some of the world’s largest aircraft’s landing gear testing frames, so there’s confidence in knowing we are qualified.

We use industry-leading ANSYS software, not any light or “express” tools. ANSYS products are used around the world by 96 of the top 100 industrial companies on the current FORTUNE Global 500 list. This powerful proven FEA simulation software helps our engineering team optimize parts by identifying weak and unnecessarily strong regions, and reduces the number of physical tests needed. To do this right and get accurate results requires proper problem setup and results interpretation, which in turn requires both the knowledge and experience we’ve earned over many years of engineering excellence.

We also take advantage of Granta’s materials databases and the Cambridge Engineering Selector (CES) software. While there may be just a few common commodity materials, there are many grades of each, and a multitude of other materials you may have never even heard of, any of which could be the right material for your product. We’re able to analyze and compare these materials to each other and, more importantly, to part requirements. We use our deep resources to make rational, traceable, and efficient decisions.

Up for Anything

Even with all this great software, there is no replacement for getting your hands dirty in the physical world. We don’t just sit at desks and theorize; we make and test real prototypes. We acknowledge the laws of physics, but are always pushing the limits to prove out something really new, better and different. This philosophy is pervasive throughout our company, and with a full machine shop and in-house rapid prototyping, it is always in practice.

Our clients have told us that when it gets tough, others just give up — but we keep going, resulting in the best design engineering solutions. We aren’t afraid to tackle the most mechanically complex problems, and are gratified when the solution results an elegantly simple product. Our decades of experience, innovative approach, fine-tuned skills, and intense focus set us apart from others who may have less skill, breadth of design capacity, and proven problem-solving ability.

Engineering Services We Offer

General Design Capability

- Product Design

- Mechanical Design

- Mechanical Engineering

- 3D Complex Surfaces

- Material Selection

- Design for Manufacturing

- Manufacturing Process Selection/Comparison

- Cost Reduction

- Design for UL, CSA, ETL, NSF agency requirements

- Test Fixture Design and Build

Analysis and Simulation

- FEA (Finite Element Analysis)

- Structural Analysis (linear, nonlinear, static, dynamic)

- Modal (Vibration Analysis)

- Thermal Analysis (steady-state, transient)

- Design Optimization

- Design of Experiments (DOE)

- Failure Mode and Effect Analysis (FMEA)

- Design and Manufacturing Feasibility Analysis

Advanced Design

- Mechanism Design

- Load and Kinematic Studies

- Valve Design

- Pump Design

- Fluid System Design

- Gasket Design, Seal Design and Selection

- Electrical Component Integration

- Electro-Mechanical Design

- Sensor Design

- Strain Gage Utilization

Advanced Research

- Alternate Material Exploration

- Metal to Plastic Conversion

- Plastic to Metal Conversion

- Component Sourcing/Selection

- Eco Analysis