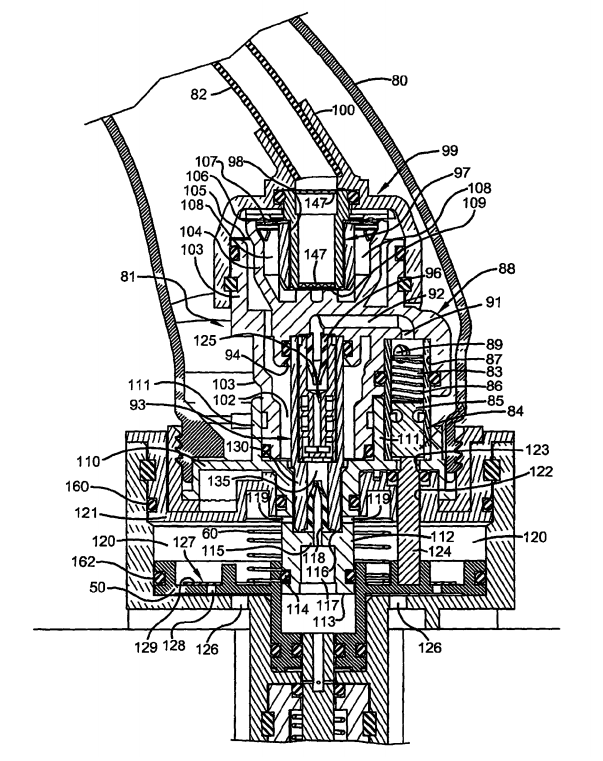

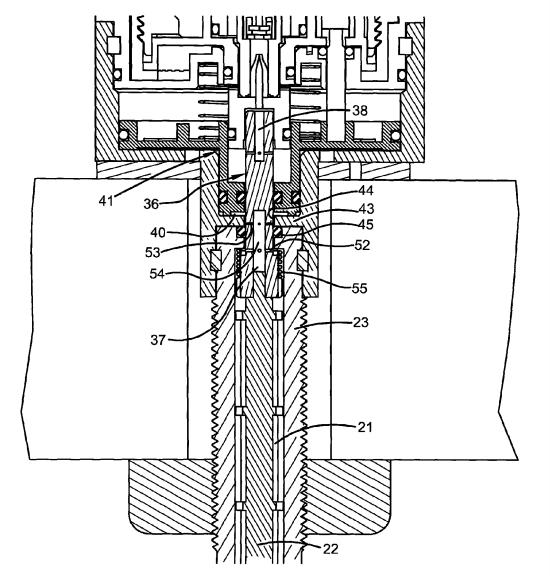

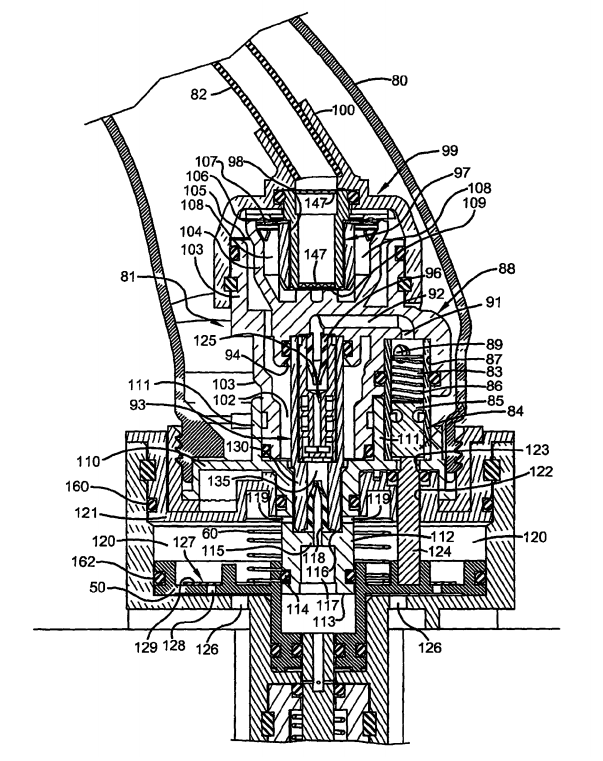

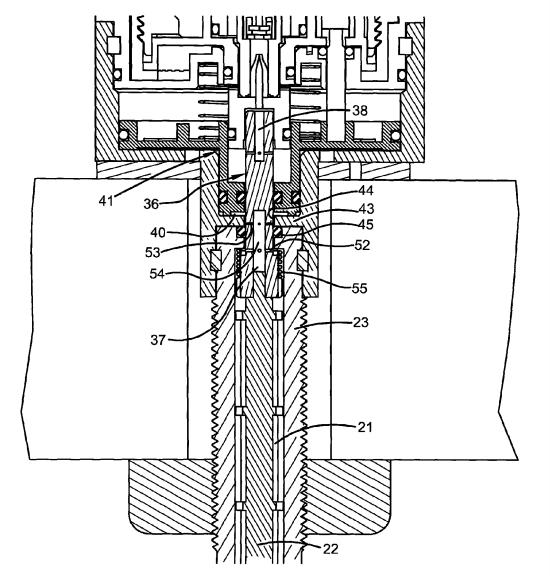

We are no stranger to the cutting edge of innovation and far-forward/fast-forward visionary thinking. Our world-class design and engineering capability resulted in valuable intellectual property being granted for a new valve design and dispensing system. The US Patent Office just recently granted GOJO Industries, Inc. a patent for a valve which we were named an inventor. From a mere idea being suggested, our innovation and engineering resulted in radical new technology, which includes a harmonious collection of of valves, springs, seals and fluid management principles.

This compact valve, shown below, operates on pressurized water, mixes concentrated product with water and then foams it all in one operation. Our unobvious ideas idea took shape through exhaustive innovative thinking, persistence in R&D, and going beyond the call of duty to prove that it works. Blazing the innovation trail is not for the faint of heart. This is yet another example of one of our trademarked phrases representing our modus operandi – “Looking Ahead. Going Beyond. Making it Real.”

We are celebrating 15 years since our humble beginnings in 2001. It all started in the basement of my house with a computer, software and a commitment to innovation, engineering and problem solving in new product development. Since then, we’ve grown into one of the most full-service product development firms in in Cleveland, Ohio and the Midwest, serving some of the largest companies across the country.

Looking back over the 5,500 days and hundreds of thousands of hours, we have solved some of the most challenging problems for some of the best known brands, through perseverance and exceptionally hard work racking our brains. We have earned the respect of many, including other design firms, by consistently solving difficult problems, applying the right manufacturing process for a given product, and overall offering excellent end results. Almost always, our work culminates in creating intellectual property as added value and client market advantage.

Our work has included medical devices, consumer products, commercial products, dispensing systems, water treatment systems, faucets, plumbing and drain systems, retail systems, electrical construction products, automotive and aerospace engineering, and so much more. Never could we have anticipated the great diversity of new products we helped create. But we’re really just getting started.

In the business world, as in life, everything happens through people. We have been so fortunate to be able to build wonderful relationships with employees, customers and suppliers. There are so many great people with which we have had the pleasure of working. We would like to take this opportunity to express our deepest appreciation to all of the wonderful people who helped us over the years.

Looking forward, there are many more opportunities to pursue and people to help. There forever will be problems to solve and improvements to make in almost any area of life, product and service. We will continue to pursue those problems and deficiencies as opportunities, turning ideas into something real. Stay tuned for more great innovations.

Paul Metcalfe

What are BIMs?

BIMs (Building Information Models) are interconnected, parametric digital representations of buildings and their components. They originated about 20 years ago and have been growing in popularity because of the value they offer to architects, engineers, contractors, building owners, and manufacturers of building products. Early BIM software developers had a vision of the benefits to an all-digital model of architecture. With everyone having access to the same digital information, there is reduction in construction timelines and misinformation made possible by vast amounts of 24/7 real-time information in text, numeric and and 3D (3-Dimensional) formats.

Just as in mechanical or electrical product design for a telephone or automobile with hundreds or thousands of components, in the AEC market (Architecture, Engineering and Construction) the buildings can be designed and managed in a digital format, with myriad advantages. The 3D digital models are object-based and tied to a database of all components which are carefully categorized and can even have 4th and 5th dimensions, for time-based values for procurement and construction scheduling, and price-based values for cost management.

What are the Benefits of BIMs?

When all of the dimensions, quantities and specific placement of products are implemented into a building digitally, there are many advantages. It’s widely understood that changes are imminent in designing anything. The many changes made in the design and construction cycle require time and associated costs. When those changes can be completed more effectively by altering the digital model, less time and money is expended. In the past, interference of components was often not detected until the construction phase, but now in the digital model, crash detection can be performed at the earliest phases of design. All of this visualization and data-rich environment has benefit to the different disciplines and phases of the building lifecycle.

Centralization of the digital information is also a significant advantage to the contractor who has to offer a proposal for the building, and has to manage through the construction management phase. Furthermore, the probability of errors or misinformation is lower and schedule delays are reduced in part because of the immediacy of information access. And when the building is complete, the owner of the building has a more effective means of managing the facility throughout its long life of maintenance and remodeling.

Once the commitment is made by a manufactuer of building products to provide their BIMs and specifications on any of the BIM repositories via the Internet, there are many ways to be found: searching for a part number, a manufacturer name, a product category and other terms. For anyone interested in better marketing their product for the building industry, it’s important to produce BIMs because they are becoming a competitive advantage; if you have a similar or identical product line to a competitor, and you do not have BIMs, yet your competitor does, the opportunity, exposure and professional perception is greater for your competition.

Who creates BIMs?

In order for building models to be digital, someone has to create them. Manufacturers of products for the building are the ideal resource to provide BIMs used by architects in their designs. The information will be most accurate and complete, and when the manufacturer provides BIMs it effectively precludes duplication of effort of individual architects across the globe, inefficiently making their own components to suit their individual needs. For building product manufacturers, offering this digital information is an important marketing advantage. It enables direct digital communication with the end user of the information.

Selection of products are based on information, so providing more professional quality information offers more opportunities to be be specified and selected. That translates to opportunities for more sales revenue. In addition to the BIMs, literature, catalogs, drawings, and engineering specifications can all be provided in one place for digital review or downloading. The more information that can be provided via this means the more effective it is for the provider and recipient. In today’s global need for speed, much work is being done asynchronously in the off hours of morning and night when other people may not be available. So having the information available 24/7 in the format needed, designers, architects, engineers, and construction professionals can do what they need uninhibited.

What software is used for BIMs?

Manufacturers of building products are likely using one of a handful of popular mechanical 3D CAD (Three-Dimensional Computer Aided Design) software systems to design and engineer their products. This 3D CAD software is not the same software used to create the BIMs. Exporting file formats from the mechanical CAD is only the beginning of creating BIMs, and even that is not always simple. So designers and manufacturers of products for the AEC market need to either acquire new software or look to the outside for a third party firm offering assistance in creating BIMs. There is much to know when offering BIMs so be prepared for a learning curve. The building industry knows that BIMs are here to stay and creating or managing this information requires an investment to participate.

In considering BIM software, there are several leading software brands that offer the capability to create and manage BIMs, such as Autodesk’s Revit and Graphisoft’s ArchiCAD. Repositories of BIMs of the many components that comprise a building, such as windows, doors, lighting, electrical and plumbing systems, and even furniture, are offered by leading websites such as Seek or ARCAT, or directly from a product manufacturer’s web site.

How can I get someone to create BIMs for my product line?

We have created BIMs for the AEC market and can assist manufacturers that need to bridge the gap from mechanical CAD to BIMs. We also have designed, engineered and tested products for the construction market with experience in plumbing, electrical, lighting, furniture, vending machines, food service, washroom/restroom systems, floor care and water treatment systems.

Further enhancing our soft goods and textile capability, we now have a Serging Sewing Machine. This gem is a 4 thread model that has varied widths and thread tension to do some very cool things in a very professional manner. Our growing client base has very broad requirements for textile-based soft goods, so we have responded with even greater capability. If you are not familiar with serging in soft goods, it is found in edges of many end products such as shirts, pants, sweaters, bags, wipers, rags, blankets, commercial/industrial filters and many other items. A serger cuts and finishes the edge of single and multiple layers of fabrics. The serged edge can be made visible for decorative purposes, or kept hidden from view purely as a functional stitch. It plays a vital role in preventing fabric from unraveling in use or during laundering. If cut fabric edges are not serged, when threads break free they can cause different kinds of problems. With adjustments to thread tension, threads per inch and and width of the stitch, creative outcomes can be produced. If you would like to know more about this or the other soft goods, textile and hard goods prototyping we can produce, we would be pleased to assist you on your next project.