Ultrasonic welding is the joining of materials through heat fusion generated by high frequency vibration. Many different plastic and metal materials can be joined using this process. We have experience in thermoplastic component welding for a variety of applications, and metal welding for electronic components. In electronics, one of the most common uses is for welding contacts to the ends of batteries or wires to terminals. We now have this ultrasonic welding capability in-house. Contact us for any of these process needs at sales@metcalfegroup.com or 440-349-5995.

Metal Ultrasonic Welding now In-House

Posted on October 17th, 2022 in News

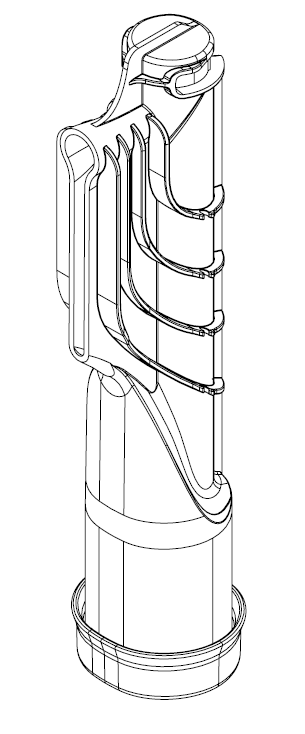

Patent Granted for Innovative Door Hinge Lubrication Device

Posted on August 15th, 2022 in News

Have a squeaky door hinge? Have you ever used an aerosol spray lubricant on a door hinge and sprayed lube where you did NOT want it, making a mess? Well, now there is Hinge Hush – a new product we developed and helped a client earn a patent to solve this problem. The product is made from flexible rubber and slips over any interior residential or commercial building door hinge, which required a lot of work to achieve. It has a vertical guide slot for the aerosol lube spray tube to only spray where you need it – on the hinge. It’s fast to install, spray, and remove and virtually eliminates the aerosol lube mess. Have a building full of doors? Meet your new friend. Any excess lube is collected at the bottom of the device in a removable absorbent material cartridge. One might ask, why didn’t someone develop this before? To learn more, see US patent number 11,220,851 B2. If you are interested in licensing this product, please contact us at sales@metcalfegroup.com or 440-349-5995.

Extensive Welding, Brazing and Cutting Capability for Metal Products and Prototyping

Posted on August 10th, 2022 in News

Welding, brazing, and cutting metals enables ideas to translate into reality, although you need the right equipment and skill. For many years we have been cutting and welding different prototypes for customers: furniture, food processing equipment, exercise and recreation equipment, pet products, and more. So we thought it was time to let you know more about this valuable and extensive capability after designs are complete. We have welding capability for TIG, MIG, arc (stick), brazing, soldering, plasma cutting and CNC cutting.

Each of these tools or methods have the right application and we can help you with that. TIG is especially useful for its ability to precisely control welding of very thin metal to thicker metals. It can be used for aluminum, steel and stainless steel. MIG uses a motorized wire feed when more speed and efficiency is desired. Brazing and silver soldering use a torch to heat parts and use different metals for the joining component. When it comes to cutting metals we can use a band saw, precise chop saw, CNC machinery, vertical mill or plasma cutting. We can also provide laser cut parts from a variety of materials. To learn more about our capability or have us quote a project for you, email sales@metcalfegroup.com or call 440-349-5995.

Multi-Color 3D Printing Capability

Posted on August 5th, 2022 in News

Printing in 3D with 2 different colors in one part is now possible with our new technology. The colors can be isolated in specific areas or throughout the part. Our leading-edge capability allows us to produce parts that really stand out. Two print heads work in coordination to enable two-color printed parts. There are different applications for this technology, including logos, names or model numbers, touch points, arrows, grips, badges, and color accents in specific areas that represents two-shot molding, even artistic items like vases or anything you can imagine. For additional information or if you have a project that can leverage this capability, email sales@metcalfegroup.com or call 440-349-5995. We would be delighted to assist you.

Duplication Mode 3D Printing

Posted on July 27th, 2022 in News, Reference

Duplication mode printing is now available internally with several new FFF printers we have. This means two print heads operate on the same part simultaneously right next to one another. That translates to faster output of the same part. Two (print) heads really are better than one. Whether the parts are large or small, we can speed up printing of parts by duplication mode printing. Not many 3D printers can do this but we find having the best technology, the best methods, and and the best people translates to the best results for our customers. To learn more about how this can help you make more parts faster than ever, email sales@metcalfegroup.com or call 440-349-5995.

Expanding Electronics Development Capability

Posted on July 19th, 2022 in News

Electronics are a growing part of our life and ever so important to many new product innovations. An increasing number of our clients have asked us to develop more complex products with electronics. So, the natural evolution was to continue to expand our capability. In addition to our experience, we have invested in additional equipment to further facilitate the development of electronic products from idea, through breadboard, PCB (Printed Circuit Board) development, software development, and into production. We work with other professionals in circuit board development, software programming, app development and manufacturing to augment our internal capability of early stage development and breadboard build and test. We have developed different measuring/detecting sensors, life safety devices, law enforcement products, pet market devices, food service products, food processing, exercise equipment, and more. This valuable combination of mechanical, electrical and manufacturing capability enables complex ideas to be managed completely by our team from idea through to production. Contact us for your next project using electronics at sales@metcalfegroup.com or 440-349-5995.

CNC Machining in-House

Posted on July 11th, 2022 in News

Continually expanding, we now have CNC machining in-house for aluminum, plastic, wood-based materials, foams and more. It’s easier than ever to quickly and accurately cut prototypes, panels, sheet, small parts, engraving, signage, machinery parts, complex hole patterns, and other items requiring more than hand-cutting or manual machining can accomplish. Housings, enclosures, panels, displays, boxes, thin, light-weight welded prototypes, and even fixtures for assembly and packaging are just some of the things we have or can process for just about any project. When combined with our design, engineering, machine shop, 3D printing, metal welding/fabrication and painting capability we are a one-stop-shop for a wide variety of projects. Contact us for your next project at sales@metcalfegroup.com or 440-349-5995.

Metcalfe Group Exhibiting at ADM Expo Cleveland 2018

Posted on February 13th, 2018 in News

The Metcalfe Group, Inc., an experienced full-service product development firm located in the greater Cleveland, Ohio area will again be exhibiting in Booth 720 at the Advanced Design and Manufacturing (ADM) Expo March 7th and 8th at the Huntington Convention Center of Cleveland in the heart of downtown. The firm is one of the most accomplished, creative product design and engineering firms in the Midwest region, serving some of the most prominent brands and best run companies. In addition to core technical, analytical and creative capabilities, business acumen is one of their strengths, in challenging innovation and entrepreneurial endeavors.

Market reach includes local, regional and national clients from start-ups, through mid-market to multi billion dollar corporations in consumer, industrial, commercial, medical, aerospace and automotive segments. Visit the booth located in the center of the Floor Plan to better understand the firm’s comprehensive capability in Research, Industrial Design, Engineering, Research and Development, Prototyping, Testing, Manufacturing, Sourcing and more.

For more information about the modern Convention Center, visit Cleveland Conventions or visit the ADM Expo show web site at Advanced Design and Manufacturing Cleveland. The address of the Convention Center is 300 Lakeside Avenue, Cleveland, Ohio 44114. For beautiful pictures of the building and surrounding area, as well as background on the design of the building, visit LMN Architects.

Metcalfe Group Sponsors Cleveland Institute of Art Career Fair

Posted on February 9th, 2018 in News

This week we were pleased to attend the first annual career fair at the Cleveland Institute of Art (CIA). The Metcalfe Group was a Gold Level sponsor of the event, which was well attended by students across all disciplines. A tour of the school revealed the diversity of the curriculum, facility and students. It is evident everywhere that the environment fosters creativity in alignment with the different disciplines.

We connected with many capable students, primarily Industrial Design majors, interested in a career in product design as candidates for a variety of opportunities at our firm. The energetic students conveyed the details of their education at CIA, shared impressive portfolios, and described future areas of interest.

From our many years of experience designing products for a variety of markets, we were able to provide insights into our friendly, creative culture, our multidisciplinary development process, and what a student might expect when working for an independent design firm.

Looking forward, we anticipate strengthening the relationship with CIA so we can both benefit. We are confident there will be CIA students in some capacity in our future.

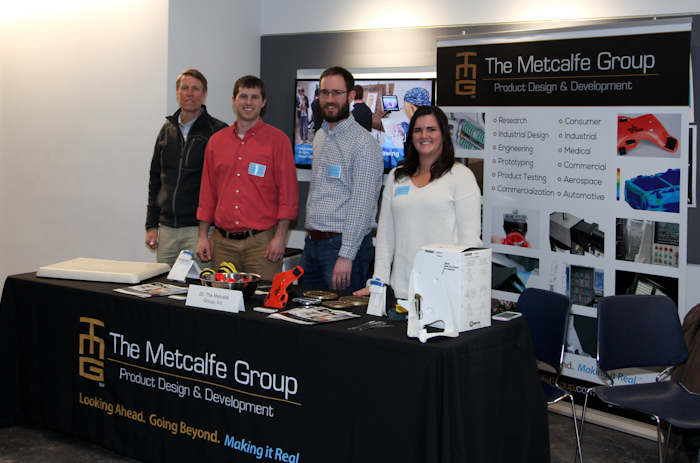

TMG Attends ADM Cleveland

Posted on April 21st, 2017 in News

At the end of March The Metcalfe Group was pleased to exhibit at Advanced Design and Manufacturing Cleveland. This show brought together a broad spectrum of industries, including automotive, medtech/medical, aerospace, and many more to show of the latest in design and manufacturing technology. The trade show was targeted to both engineers and executives, and we enjoyed getting to meet many of them. It was great to show off our design and engineering skills in our booth as well as walk the show and learn about the latest in robotics, automation, plastics, packaging, machining, molding, and design/engineering technology. It’s always a pleasure to catch up with previous clients and network with like minds in our industry.